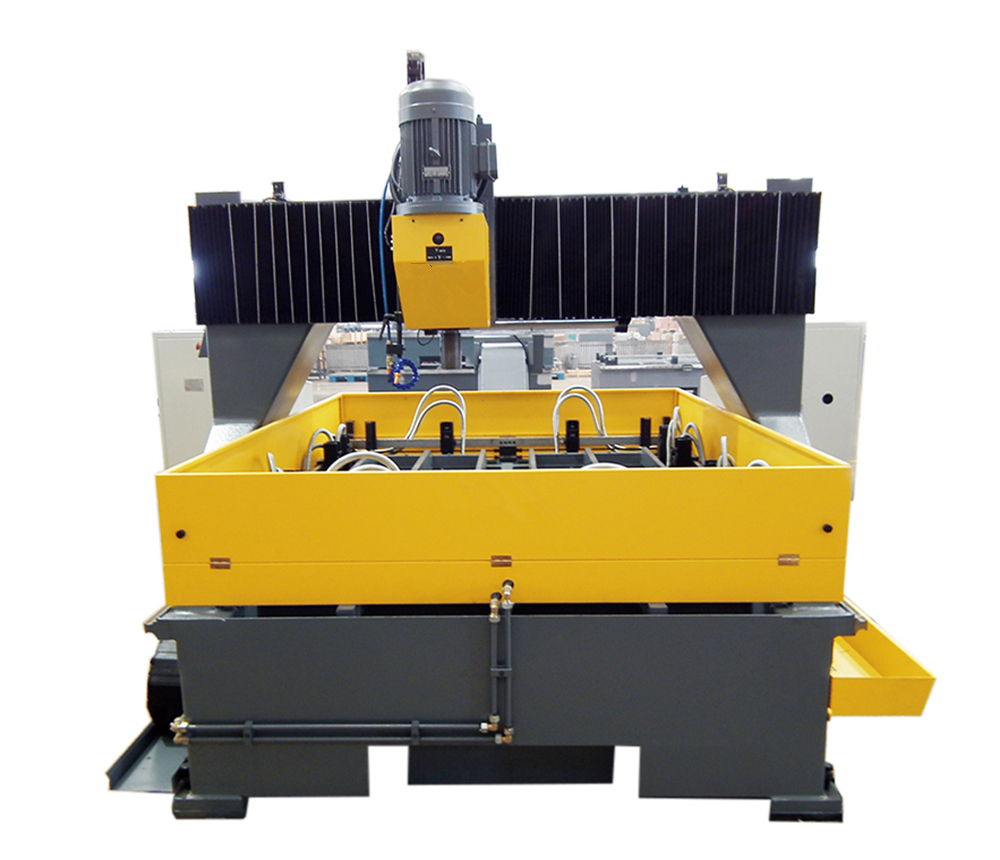

Model | PZ2012 | PZ2016 | PZ3016 | ||

Max size of work piece(mm) | one piece | 2000×1000 | 2000×1600 | 3000×1600 | |

two piece | 1000×1000 | 1600×1000 | 1600×1500 | ||

four piece | 1000×500 | 800×500 | 1500×800 | ||

Max. thickness of work piece | 100mm, can overlap processing for thinner plates | ||||

Morse taper | #4 | ||||

Max. drilling diameter | Φ50mm | ||||

Drilling spindle | Rotating speed(rpm) | 120-560( Stepless speed adjustment) | |||

Max. feed stroke(mm) | 350 | ||||

Motor power(kW) | 5.5 | ||||

No. of champs | 12 | ||||

Motor power(kW) | Servo motors | X axis | 1.3 | ||

Y axis | 1.3 | ||||

Z axis | 0.85 | ||||

Weight(t) | About 5.3 | About 6.3 | About 7 | ||

Overall dimensions(L×W×H)(m) | About 4.5x2.2x2.8 | About 4.5x2.6x2.8 | About 5.5x2.6x2.8 | ||

Application Industry:

It is used for drilling metal plates and flanges of building, bridge, steel tower and steel structure industries. It adopts gantry type structure. The axis X, Y and Z are drove by servo motor through precise ball guide screw. It positions automatically, precisely and quickly and finishes the processing of drilling automatically.

Product feature:

1. The machine can clamp 4 work-pieces at the same time.

2. Chip removal automatically, cooling liquid recycling used.

3. Drilling head has stroke self-controlled function, it can automatically convert from fast feeding to normal feeding without setting the thickness of work-piece and the length of the drilling head.

4. Electrical control adopts upper computer plus PLC control, direct conversion of CAD/CAM. It also can process NC file which generated by TEKLA.

中文

中文 English

English